The Challenge

A rare explosion on a major university campus led to the closure of two dormitories, including a campus dining facility, displacing more than 1,300 students. The damage led to the need for a new dining facility that would require 14 serving lines be designed, engineered, manufactured, and installed in under four weeks

The Solution

Duke’s representative, Inform Marketing was approached with the university’s predicament and a floor plan. Inform knew Duke’s team at CounterCraft™ was the team for the job. Presented with the challenge, CounterCraft™ worked quickly and fiercely, exhausting every resource to build 14 counters in an unprecedented time frame. With teamwork, open communication, hard work and a dedicated effort, the team pulled off the feat designing, engineering, manufacturing, shipping, and installing the counters in under four weeks’ time. This effort minimized the downtime for students to the minimum allowable time and gave the University the capacity to begin feeding the 1,300 students that were affected again.

The counters built for UNR featured:

- 2cm Thick Engineered Stone countertop w/4” Splash at Wall in Silestone- Blanco Maple

- Décor – ¾” Laminate Doors/Removable Panels in Wilsonart- 7965 Walnut Heights

- Drop-ins – Hatco Hot Soup Wells, Hatco Hot/Cold Wells, Hatco Cold Pans, Hatco Hot Food Wells, Sinks, and Recessed Heated Shelves,

- Both Adjustable (BGA) and Fixed (BG) Food Guards

PRODUCTS FOR SUCCESS

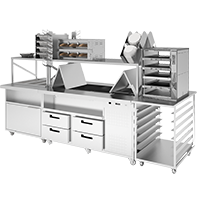

418 Series Economy Production Worktable

Features 18-gauge, 400 Series Stainless Steel tops, galvanized steel …

416 Series Standard Production Worktable

Features 16-gauge, 400 Series Stainless Steel tops, stainless or …

316 Series Deluxe Production Worktable

Features 16-gauge, 300 Series Stainless Steel tops, stainless or …

314 Series Supreme Production Worktable

Features 14-gauge, 300 Series Stainless Steel tops. Stainless or …

400 Series Food Guards

Your customers want a fresh, clean and easy-going experience. We’ve …